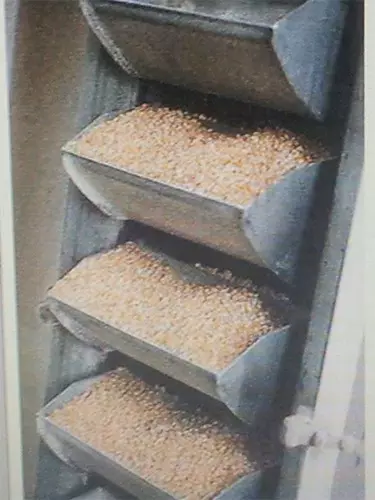

Bucket Elevator

The Bucket Elevators are an essential part of many conveying and storage systems dealing with powdered or granular materials. Being simple and robust in design and easily maintained, they provide low cost versatile handling equipment with many applications in manufacturing and processing factories. It uses the bucket to contain powders, particles or small bulk materials, and then elevates the bucket in a vertical and continuous way, have been continuously developed over many years to provide customers with a wide range of options to suit every requirement and a design that ensures easy assembly, installation and maintenance. The modular design allows any configuration to be easily and quickly built up to suit a customer's exact requirements.

Dayal Bucket Elevator are in operation in many different industry sectors handling a huge variety of bulk materials:-

Foods - flour mill, atta mill , daliya mill, rice mill, corn mill, besan mill, cleaning, grinding, pulses (daal) mill, feed mill, spices, etc.

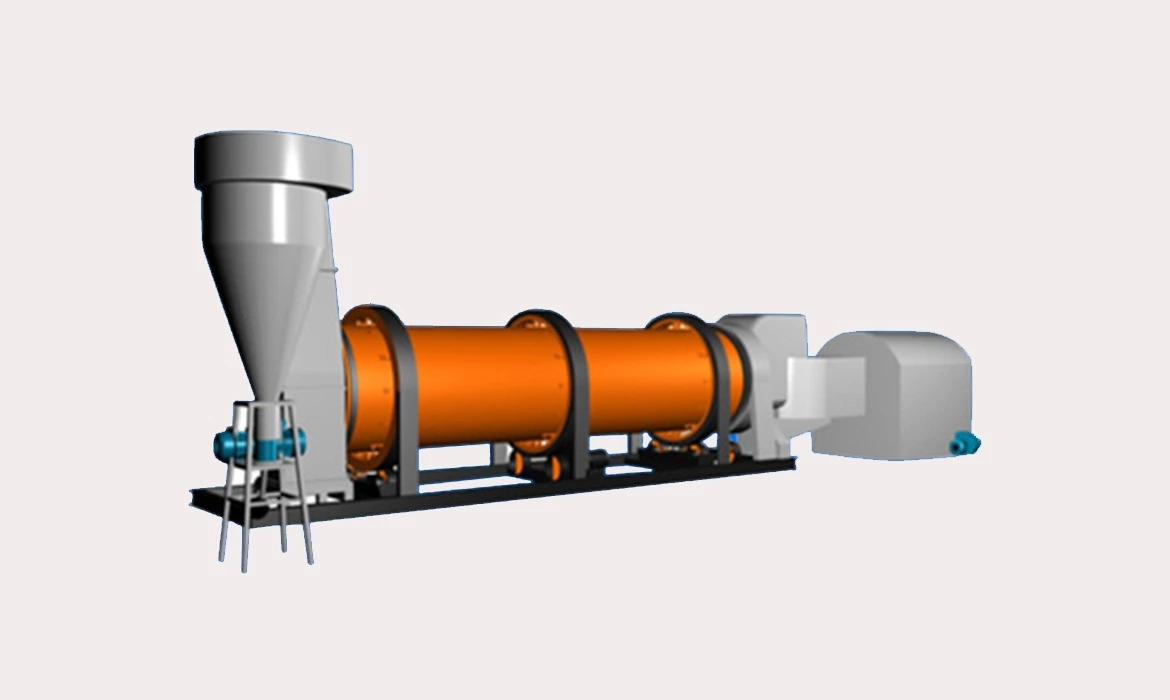

Head Section

- Low-impact head design.

- Split –style hood allows for easy inside accessibility.

- Adjustable back flow sheet in the discharge hood.

- Interior lip to keep moisture out and dust in.

- Provision of reverse back stop arrangement directly mounted on the shaft to avoid fall back of the material during

- power breakdown.

- Rubberized pulley to prevent friction between the inside of the belt and the pulley to reduce wear & tear of the belt.

Intermediate Section

- Sections are built square/rectangle ¶llel for free hassle construction.

- Fixed type free port is placed in two position on inspection section.

- Inspection section facilities belt, and splice installation.

- Large removable panels on inspection section.

- Dust-tight & weather-tight protection.

- All section are bolt able type.

Boot Section

- Hat section type brackets at bottom for maintenance and easy anchoring.

- Ribbed type crowned pulley is provided for self cleaning.

- Corrosion -resistance Acme screw take-up.

- Bolted construction for easy repair and maintenance.

Safe Operation & Explosion Control

- Off-track & zero-speed detectors.

- Reverse back stop arrangement.

- Pressure relief.

- Sensor for dictation overflow.

Platform with support

Dayal Engineering manufacture in-house a complete range of support towers, ladder and safety cages & service platform to suit new or existing installation for inspection, lubrication &mechanical/electrical services. Dayal Engineering design is simple and robust which comes ready to bolt construction at site.

Technical Data

| Bucket Elevator Type | Dimensions (mm) | ||||||||

| A | B | C | D | E | F | G (mt) | H | I | |

| D BE-100 | 190 | 1205 | 816 | 554 | 190 | 594 | 1-40 | 673 | 190 |

| D BE-125 | 205 | 1423 | 965 | 646 | 205 | 712 | 1-40 | 740 | 265 |

| D BE-150 | 230 | 1613 | 1080 | 836 | 230 | 810 | 1-40 | 836 | 240 |

| D BE-200 | 284 | 1642 | 1203 | 895 | 290 | 1029 | 1-40 | 930 | 284 |

| D BE-250 | 350 | 2123 | 1496 | 1112 | 350 | 1312 | 1-40 | 1199 | 382 |

| D BE-300 | 432 | 1910 | 1916 | 1300 | 432 | 1600 | 1-40 | 1416 | 620 |

| D BE-350 | 482 | 2060 | 1936 | 1425 | 482 | 1750 | 1-40 | 1466 | 670 |

| D BE-400 | 562 | 2110 | 1956 | 1445 | 562 | 1900 | 1-40 | 1510 | 750 |

| D BE-450 | 612 | 2260 | 1976 | 1470 | 612 | 2050 | 1-40 | 1560 | 800 |

| D BE-500 | 712 | 2310 | 1996 | 1500 | 712 | 2200 | 1-40 | 1616 | 900 |

Note :

Material of construction for Bucket Elevator : MS Powder coated/ Galvanized Steel/ Stainless steel.

We have required details for design a suitable model : (Product Name or Density, Capacity & Length with inlet & Outlet.)